Stone, Marble & Concrete Coatings

Stone & Marble Coatings

Comparison of Stone Coatings

| Properties | 695 Product Page |

7641 Product Page |

7622 Product Page |

8637 Product Page |

704/705 Product Page |

7620 Product Page |

7626 Product Page |

|---|---|---|---|---|---|---|---|

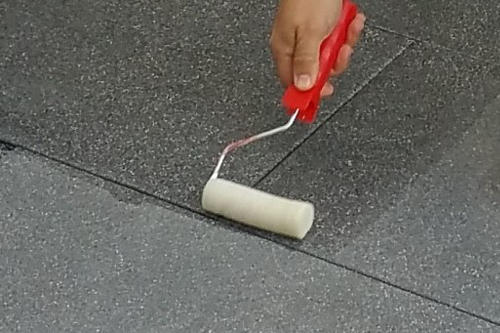

| Application | Spray, brush, roller | Spray, brush, roller | Spray, brush, roller | Spray, brush, roller | Spray, brush, roller | Spray, brush, roller | Brush, roller, convention or airless spray |

| Application Temperature | <5°C - 50°C | <15°C - 25°C | <5°C - 30°C | <5°C - 30°C | <5°C - 40°C | <-10°C - 70°C | <-5°C - +60°C |

| m² per liter | 5 - 40 | 50 - 80 | 10 - 20 | 10 - 20 | 20 - 100 | 8 - 50 | 8 - 10 |

| Durability | Up to 2 years | Up to 10 years | Up to three years | Up to 10 years | 5 years + | 10 - 20 years | Up to 20 years |

| Curing Time | 12 hours | 7 days at room temperature | 12 hours | 12 hours | 24 hours | 3-6 hours at 20°C | Touch dry 3-4 hours, full cure 24 hours |

| … based | Water | Solvent | Water | Water | Solvent | Solvent | Solvent |

| Available as concentrate | Yes, 1:9-1:14 (art. no. 697) | No | No | No | Dilutable up to 1:1 with Ethanol or 1-Methoxy-2-Propanol | No | No |

| Breathable | Yes | No | Yes | Yes | No | Yes | Yes |

| Visible | No on most surfaces | Yes, glossy | No on most surfaces | No on most surfaces | Yes, glossy | Might be slightly darker | Yes, clearly (glossy) |

| Topographical / penetrative | Topographical | Topographical | Topographical | Topographical | Topographical | Penetrative, extreme abrasion-resistant | Topographical, very strong bonding |

| Oil resistant | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Frost resistant | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Available in RAL colors | No | No | No | No | Yes, from 1.000 liter | No | Yes, from 100 liter |

| Dangerous goods | No | No | No | No | Yes | No | No |

| Application recommendation | Concrete, plaster, natural stone (granite, slate, basalt, sandstone, | Concrete, plaster, natural stone (granite, slate, basalt, sandstone, | Wet room walls, concrete seating in public areas, stone foyer areas | For monuments, Statues, high value stone art works, paving-stone systems and terrace tiles | Concrete, plaster, natural stone (granite, slate, basalt, sandstone, limestone), roof tiles, clinker | Concrete, tiles (unglazed), roofing tiles, brick/masonry, limestone, sandstone, mineral plaster, natural stone, façade, slate | Graffiti Protection for up to 50 times, for commercial locations, for aluminium siding, (fibre) glass, masonry, metal, street signs, stucco, utility boxes, vinyl siding, wood |

More Information & Videos

- Flyer: Stone Coatings (PDF)

- Stone Coatings Comparison (PDF)

- Product Sheet: 620 Stone, Mineral, Concrete Coating + 7620 Penetrating Stain Protector (PDF)

- Product Sheet: 704/705 Multi Stone - Stone, Concrete, Mineral Surfaces Coating (PDF)

- Product Sheet: 7641 Q² Marble PRO Marble Protection System (PDF)

- Product Details: 7641 Hybrid Coating (PDF)

- Product Sheet: 7622 Eco-Stone Topographical Hydrophobic Protection & 8637 High-performance Protection for Monuments (PDF)

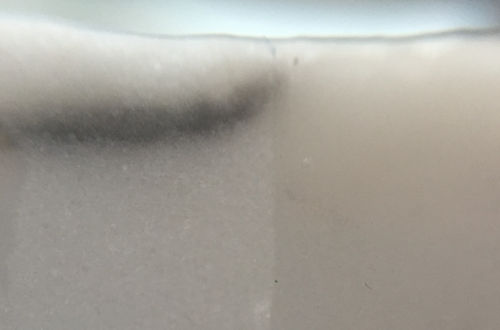

- Product Test: Anti-Mold Effect of 7620 Stone Coating (PDF)

- CCM wins the „South West England Prestige Award 2021/22“

P-OFF Urine Repellent Coating

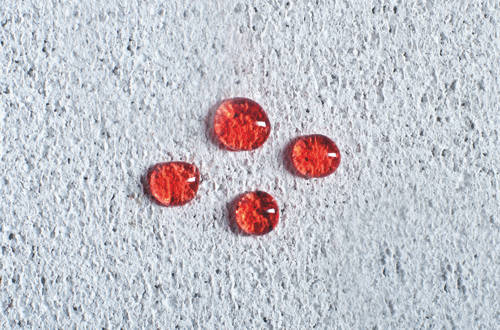

Special nano scale coating which is highly suited to protecting stone work from urine. Prevent of urine penetrating and damaging the stone work. Makes cleaning a great deal easier and it also prevents lingering odour created by urine being absorbed into the stone work.

More information on request.

Marble Coatings

Marble (and similar calcite-based stone) is highly reactive to acids in both liquid and gaseous form. 7641 Hybrid Coating is a two-component high-performance coating technology that makes coated marble so resistant that, for example, lemon juice and wine will not penetrate and/or damage the surface for 12 hours.

More Information

Concrete Coatings

Our concrete additives are extremely well suited as hydrophobic concrete-additive for the manufacturing of paving stones, concrete slabs and prefabricated concrete elements. They improve concretes compaction, regulates the capillary properties of the concrete and reaches a durable reduction of water absorption. The final product is protected against rising moisture. They protect the concrete against limeefflorescences and against the growth of micro-organisms in the product (moss, algae, fungus) The final concrete-product remains vapour-diffusive. They minimises sticking to the stamp and sticking to the concrete-mixer by using a highly-effective non-stick additive.

Product Comparison for Concrete Coatings

| Property | 627-10 | 8628 |

|---|---|---|

| Basis | Siloxan | Silan |

| Hydrophobicity effect | Yes* | very strong |

| Protection against lime efflorescence | Yes | No |

| Prevents concrete-sticking in concrete mixer | Yes | No |

| Prevents concrete-sticking of press-plunger | Yes | No |

| Capillary regulating characteristic | Yes | Yes |

| Vapour diffusive | Yes | Yes |

| Plasticising properties (reduces brittleness, less cracking) | Yes | No |

| Highly stressable stabilization | Yes | No |

| Extremely weather-resistant | Yes | Yes |

| Frost and de-icer resistant | Yes | Yes |

| Alcali resistant | Yes | Yes |

| Oleophobic | Yes | Yes |

| Breathable | Yes | Yes |

* 627 is ideal for „flow“ concrete. It offers some degree of hydrophobicity but attain a strongly hydrophobic concrete one should use 8628.