Industrial & Pro Coatings

High Performance Coatings

Best coatings for highest standards

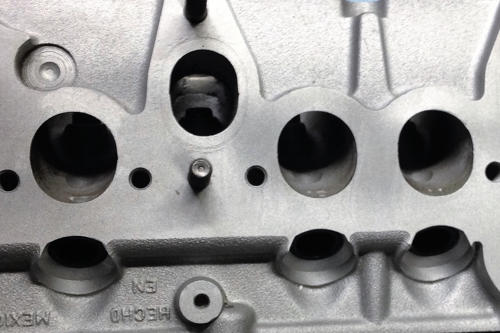

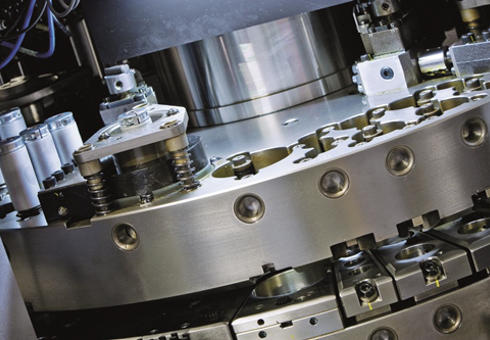

These are highly advanced SiO² coatings which were created to address the needs of the marine, military and aerospace sectors. They are massively resistant to corrosion, abrasion and temperature. They can be applied to metal, plastic, powder coated and painted substrates. The coatings can be heat cured, or cured at ambient temperature. They react with the substrates surface and forms an abrasion resistant coating with very high bonding properties on metal. It generates thin, transparent coatings with high impact strength and is resistant to alkali, abrasion and corrosion.

Downloads & Details

- Product Sheet: 640 Permanent Protector / 7640 Profi Protect (PDF)

- 640 / 7640 Permanent Protect (product page)

- 7641 Hybrid Multi Protect (product page)

- 643 Metal Dura Easy On (product page)

- Instructions: Application of 7640 on Car Paintings and Rims (PDF)

Product Comparison

| Properties | 640 Permanent Protect Product Page |

7641 Hybrid Coating Product Page |

643 Metal Dura Easy On Product Page |

|---|---|---|---|

| Type of Polysilazan | Organic | Hybrid | In+organic |

| After bonding arises… | SiO² with organic rests | SiO² with organic rests | Pure SiO² |

| Temperature resistance | Appr. 800°C | -40° - 350°C | >1.000°C |

| Chemical binding with the surface? | Yes | Yes | Yes |

| Vitreous layer? | Yes | Yes | Yes |

| Hydrophobic surface? | Strong | Medium | Weak |

| Application on… | Metals, alloys, plastics, paints, glass and stone (e.g. marble and granite) | Metals, alloys, plastics | Metal, plastics, paintings, glass, stone |

| Application | Spray, dip or polishing | Wiping, rolling or spraying | Spray or dip |

| Resistent against… | Variety of mild to medium strong acids / alkalis | Mild to medium strong | Mild to strong acids/alkalis |

| Scratch and impact resistance | High | Medium scratch, high impact resistance (very flexible) | Extreme |

| Corrosion and oxidation protection | Permanent | Up to 15 years | Permanent |

| Salt resistance | According to DIN 50021 | ||

| Food safe | + | ||

| Weathering test mild steel, brass, copper, bronze (ISO 2810, 700h) | + | ||

| CASS-Test aluminium (DIN 50021, 240h) | + | ||

| Corrosion test hot dip galvanized steel (DIN 6270, 768h) | + |