643 Metal Dura Easy On - Metal Coating

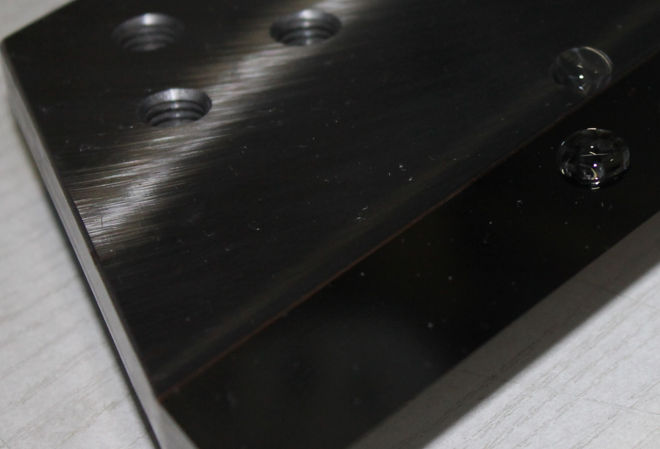

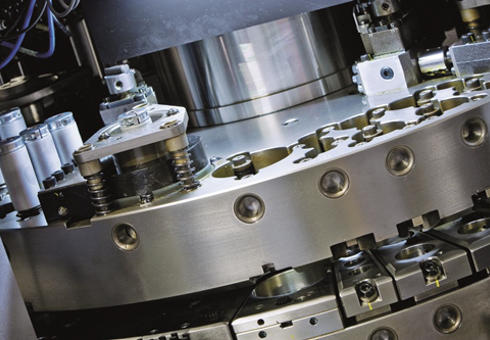

643 Dura Easy On Metal Coating is the newest generation of ceramic coatings. This coating off ers high water and dirt repellency linked with high durability against mechanical wear on synthetic or metallic surfaces. Inorganic groups give 643 Dura Easy On perfect adhesion to the substrate and a pencil hardness of 9H. This coating can be multi layered.

Key Features

Application Temperature

Coverage Rate per Liter

(one layer)

Durability of the Coating

Shelf Life of the Liquid

Storage Temperature

Curing Time

6-7 days for abrasion resistance

Downloads

Properties

- Ceramic / hybrid based substances

- Based on Silicon, with Hydrogen and Nitrogen bonding

- Pencil hardness up to 9H (harder than car paint)

- Room temperature curing or heat curing possible

- Permanent easy-to-clean effect

- Outstanding UV/weather-, abrasion and chemical resistance

- Withstands strong acid and domestic grade alkalines

- Chemically inert

- Transparent, virtually invisible

- Color deepening possible by application of several layers

- Food-safe

- Strong chemical bonding

- Free from Halogens

- High temperature-resistance up to 600°C

- Usable as an anti-graffi ti coating

- Corrosion inhibiting characteristics

- Barrier properties

- Stain guard against acid (ph 2 to 12,5)

- Simple application (wipe or spray application, dipping is not recommended)

- Can be layered, (up to 3 layers)

- Contact angle 105°

How To

Clean the surface thoroughly with a residue-free cleaner. For carpaints, we recommend butyl acetate. When applying manually it is suggested that a gentle circling motion is utilized in order to ensure that no visible surplus is evident, (if required, this process be repeated up to 3 times, at intervals of 5-10 minutes in order to increase the layer thickness.) The coating becomes water-resistant after 24 hours and becomes fully cured against mechanical abrasion and chemical within 7 days. The drying time and hardness of the coating can be enhanced by the application of heat, eg apply 80°C of heat for 30 minutes to the coated item, then allow the item to cool for 3 hours, after which the coating will be fully cured.