Made in Germany

TiOSEPT®

Anti-microbial Liquid Glass Coating

Effective for up to 18 months

- Flyer TIOSEPT® (PDF)

- TiOSEPT Clearance Certificate (PDF)

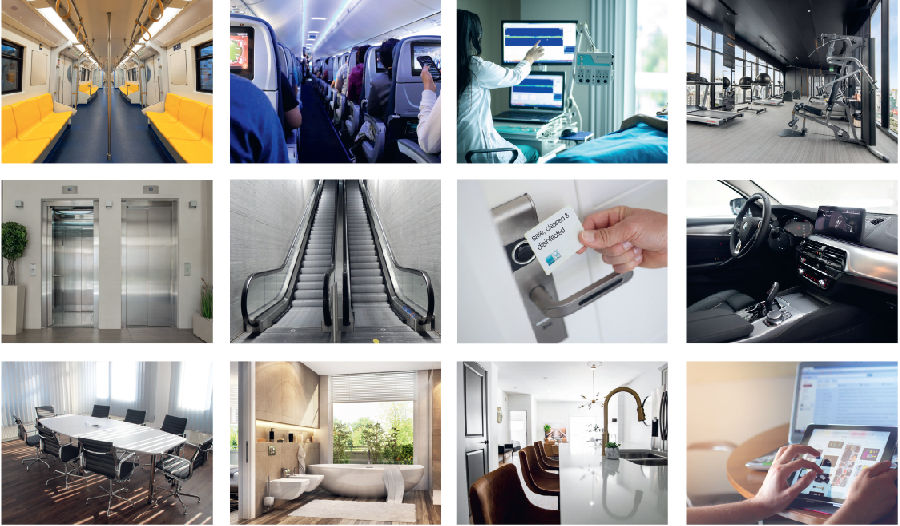

For smooth surfaces

Glass and ceramics, stainless steel, aluminum, plastic & painted surfaces

FAQ

1Can TiOSEPT® be applied to plastics?

Application on PE, PP, melamine resin & polycarbonate is possible (e.g. on light switches, table tops etc.)

2Can TiOSEPT® be used on stainless steel/metal surfaces, e.g. handrails, outdoors?

Yes, this is possible.

3What is revolutionary about the TiOSEPT® technology?

People have been using silver as a remedy against bacteria for thousands of years. The first recorded uses were in China 3500 years ago. There is no doubt that silver is an effective antibacterial agent, but it has to be the "right kind" of silver, used in the right form. This is especially true when silver is incorporated into coatings. In the mid-2000s, silver was used in refrigerators, paints, coatings, etc. In most cases, the silver used for these applications was in the form of "silver ions". This technology worked very well for a short time, but after a few weeks the performance dropped dramatically, so we developed a solution which allowed us to incorporate silver into our ultra thin "liquid glass coatings" and also keep it stable and effective for a prolonged period.

We found that the addition of "silver chloride" is the ideal form of silver as it integrates well into our coating and most importantly it provides long-term protection against a wide range of micro-organisms (bacteria, fungi and viruses). At the same time the coating is harmless to humans, animals and the environment and complies with German and Austrian biocide regulations.

The technology has been tested for high level efficacy by independent laboratories, e.g. TÜV and Hohenstein.

We found that the addition of "silver chloride" is the ideal form of silver as it integrates well into our coating and most importantly it provides long-term protection against a wide range of micro-organisms (bacteria, fungi and viruses). At the same time the coating is harmless to humans, animals and the environment and complies with German and Austrian biocide regulations.

The technology has been tested for high level efficacy by independent laboratories, e.g. TÜV and Hohenstein.

4Does Tiosept® fulfill food grade standards?

Yes, Tiosept® is food grade (see document above).