Nano-Scale Liquid Glass Coatings | Plastics & Metal

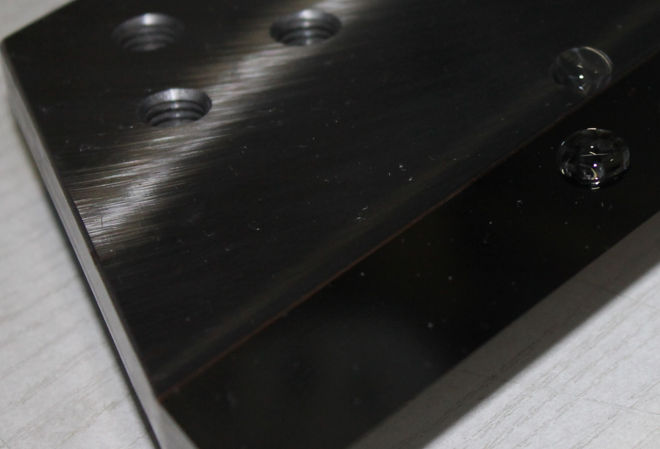

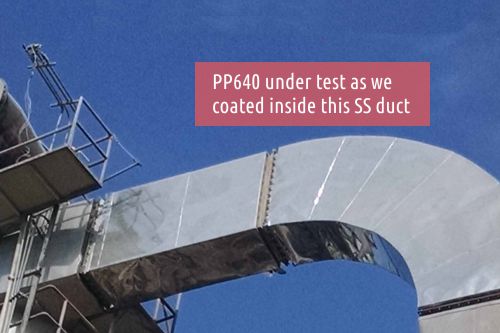

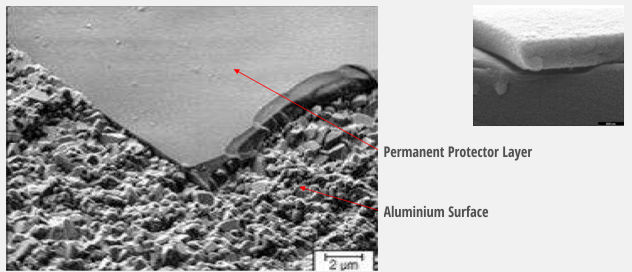

640 Permanent Protector

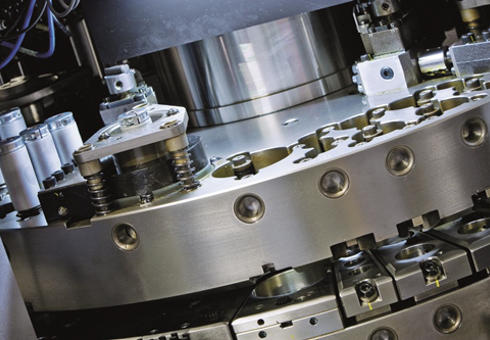

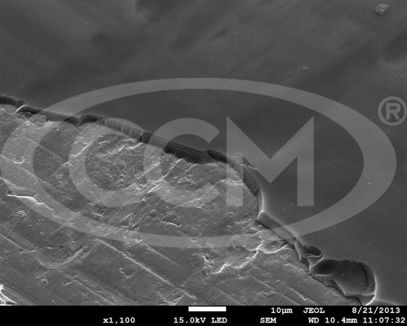

These are highly advanced SiO² coatings which were created to address the needs of the marine, military and aerospace sectors. They are massively resistant to corrosion, abrasion and temperature. They can be applied to metal, plastic, powder coated and painted substrates. The coatings can be heat cured, or cured at ambient temperature. 640 Permanent Protector react with the substrates surface and form an abrasion resistant coating with very high bonding properties on metal. They generate thin, transparent coatings with high impact strength and is resistant to alkali, abrasion and corrosion.

Downloads & Videos

- Product Sheet: 640 Permanent Protector / 7640 Profi Protect (PDF)

- Presentation: Corrosion Protection Permanent Protector (PDF)

- Instructions: Application of ALGT Permanent Anti-Corrosion Coating (PDF)

- Insights: Permanent Protector Hardeness (PDF)

- Instructions: Application of 7640 on Car Paintings and Rims (PDF)

Key Features

| Attribute | Details |

|---|---|

| Application Temperature | -5°C to +35°C |

| Coverage Rate per Liter | 40 to 100m2 |

| Durability of the Coating | Up to 25 years |

| Shelf Life of the Liquid | 24 months when stored in original containers, 6-12 months after opening |

| Storage Temperature | +5°C to +20°C |

| Curing Time | 5-7 days at 20°C, 1 day at 60°C (surface usable after 1 hour), 2 hours at 200°C |