643 Metal Dura Easy On

Quartz Ceramic Coating

643 offers high water and dirt repellency linked with high durability against mechanical wear on synthetic or metallic surfaces. Inorganic groups give 643 Dura Easy On perfect adhesion to the substrate and a pencil hardness of 9H.

Downloads & Videos

FAQ

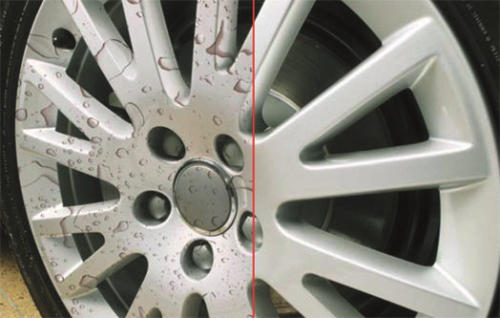

Our 7640 Q² Quartz Ceramic Coating Coating is a glass like coating based on silanes. The coating can be applied as either a thick layer of approximately 10 microns on to surfaces which are not highly reflective or the coating can be applied and then buffed thus reducing the coating thickness to approximately two microns. This latter procedure is normally used in the auto sector. The coating is neither paint, wax nor a sealant, and cannot flake off or be washed off. The coating forms a durable (“covalent”) bond with the paint, and it can only be removed by strong abrasive forces. The coating cannot be dissolved by standard chemicals which are commonly used in the auto sector. The coating provides a highly glossy appearance but like all surface abrasion will eventually impact on the coating. The useful life of the coating will depend on the amount of abrasion that the surface is subjected to.

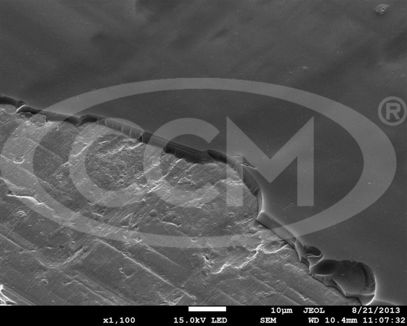

We use the familiar “pencil hardness” to describe the hardness of a layer. The measuring range is between 6B (smoothest) and 9H (hardest). The Auto and Aerospace 9H Ceramics Coating achieves a hardness grade of 8H (drying at indoor temperature) up to 9H (heat drying).

The hardness of a coating is measured when the coating is applied to a metal test bed. If the coating is applied to a soft painted surface the hardness of the coating will remain constant, but the underlying soft painted surface and the coating can be distorted if point loading pressure is applied.