Car Coatings

7650 Permanent Pro Easy On

The First Ceramic Coating For Non-Professionals With Outstanding Performance

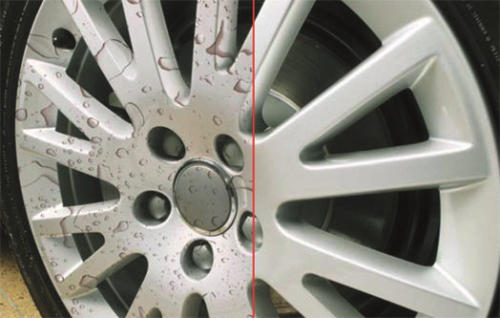

This highly advanced coating has been specially developed for the demanding requirements of the auto, aviation, marine, military and transport sectors. It is extremely resistant to corrosion, abrasion, and temperatures, and can be applied to metal, plastic, powder-coated, and painted surfaces.

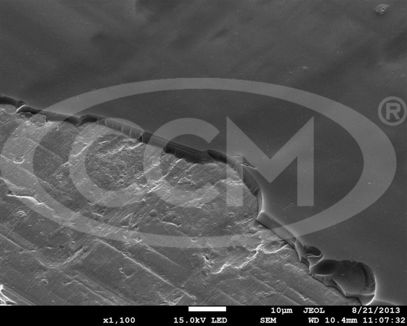

Curing can occur at ambient temperature but the additional application of heat is also advantageous. The coating forms an extremely strong bond with the surface, and creates an abrasion-resistant finish with very high resistance to solvents.

The thin and transparent coating possesses extreme stability, and a degree of hardness up to 9H can be achieved. Suitable for all kinds of vehicles (including vintage cars), motorcycles, caravans, and boats.

Downloads & Videos

- Flyer: 7650 Permanent Pro Easy On - Quartz Ceramic Coating (PDF)

- Flyer: 7650 Permanent Pro Easy On with Coating Kit (PDF)

- Application Instruction: 7650 Permanent Pro Easy On (PDF)

- FAQ: 7650 Permanent Pro Easy On - Observations On Appearance (PDF)

- "7650 DIY Ceramic Coating Explanation"

- About the potential of car coatings

FAQ

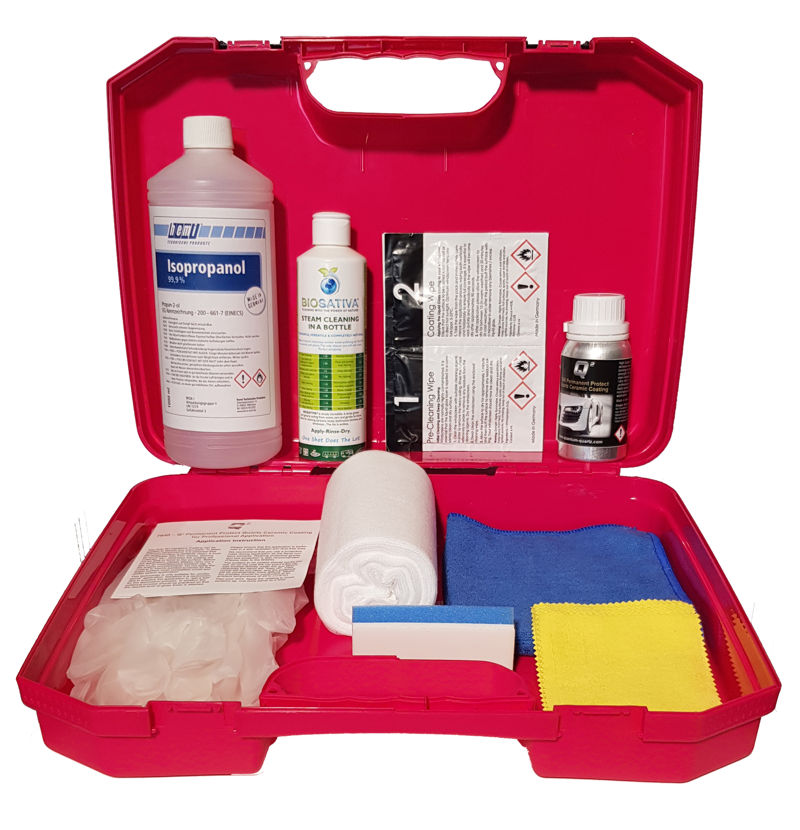

7650 Professinal Car Coating Kit

- 250 ml Biosativa® Bio Cleaner Concentrate 1:10-1:50 (pre-cleaner)

- 1 liter IPA (isopropyl alcohol = pre-cleaner for degreasing)

- 1 roll dry wipes, 100 pcs., 25 x 16cm

- 1 application sponge (to put around the wipe)

- 5 yellow application microfiber wipes, 10 x 10cm

- 1 blue polishing microfiber wipe, 30 x 30cm

- 6 one way gloves

- 100 ml 7650 Professional Coating for Car Painting

- 1 instruction for application

- 2 windscreen double-sachets (each for approx. 6 months)

- Kit packed in plastic suitcase

| Attribute | 7650 |

|---|---|

| Application | Skilled or competent DIY |

| Application Temperature | 5 to 35°C |

| Durability | Up to 48 months |

| Curing Time | 7 days at room temperature (car useable after 5 hours) |

| Pearl effect | High to v-high |

| Gloss effect | High to v-high |

| Scratch resistance | +++ |

| ML per mid range car | Approx. 50 ml |

| Constituents | Liquid multi solvent-based |

| Resistant to frost | Yes |

| Resistant to UV | Yes |

| Toluene-free | Yes |