Hybrid Nano Silica Fusion Technology

The Fabric Industry has been searching for a coating which offers the same performance as C8 (PFOA) technology, yet without the obvious negative attributes. It became apparent that a technology based on SiO² could prove to offer the solution, and this has indeed proven to be the case.

The new Hybrid coating, which also utilises an environmentally optimised, slightly cationic, C6-carbonfluoropolymer, is PFOA-free, stunningly Hydrophobic and Oleophobic, Self Healing and most importantly Machine Washable.

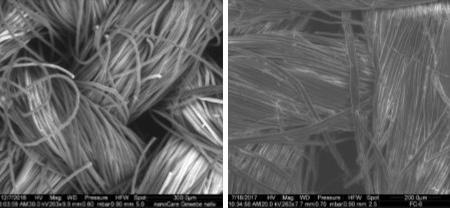

Fabrics coated with HFNSF technology after 15 wash cycles

Downloads

HNSFT with self-healing characteristics

Our experience of working with SiO² based coatings informed us that this technology offered us the best foundation from which to create a new coating.The main obstacle to overcome was “enhancing the bonding characteristics of the coating”. This obstacle was overcome by creating a hybrid matrix, which, when heat cured would provide a coating which would not only match but supersede the performance characteristics of standard C8 fabric coating technology.

Attributes

- PFOS and PFOA free

- F-C Modified silica. The fluorinated component is very strongly bonded to the SiO².

- Bonded structure massively reduces degradation of the coating.

- Outstanding oleophobicity oil repellency 8, ISO 14419 (depending upon fabric type)

Technical Data

- Washing stability 25-100 washing cycles

- (AATCC) Test Method 135, ECE formulation washing powder, non-phosphate reference

- Oil repellency: ISO 14419 / 8-6 (depending on the substrate)

- Self-healing prompted by tumble drying

- Water repellency: AATCC 22 / 100, ISO 4920 / 5

- Temperature stability: 220°C

- Transparency: 100%

- Outstanding UV-stability > 3.500 hours

Industrial Application

The constituents are supplied in four different concentrates.

For creating 1.000 liters the amounts are:

Component 1 - 10 liters

Component 2 - 30 liters

Component 3 - 10 liters

Component 4 - 8 liters

Simply mix the constituents into water to create the HNSFT coating.

Pre-drying at 100°C is recommended as the fabric must be dry before “curing”.

Curing: Approximately 60 to 120 seconds at 150-175°C.

Curing times and heat settings can be adjusted to match fabric types and production methodology.

Foulard application is recommended.

Stability of mixed coating: 2 days

Shelf life of the components: 1 year

uncoated (left) | coated (right)

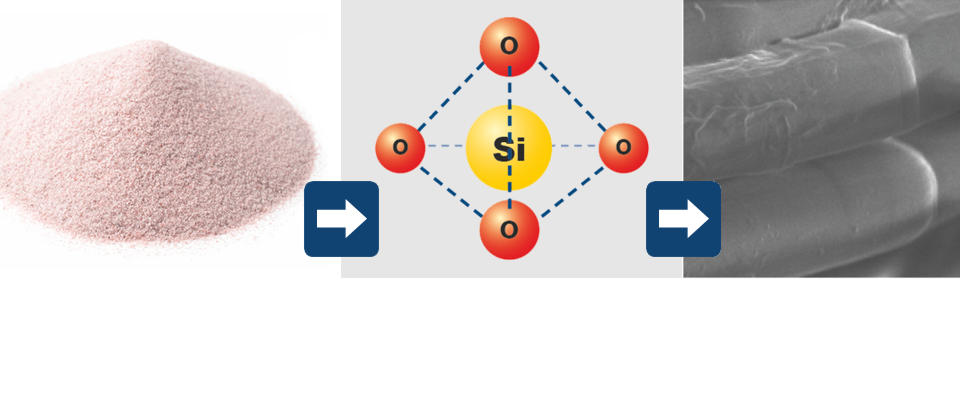

From Quartz Sand to a revolutionary Liquid Glass Technology Coating

The key component within our coating is nano scale silica

Background

C8 technology was identified as being profoundly persistent in the general environment and specifically within humans and as a result Greenpeace thankfully launched a campaign in order to ban the use of this technology; however, this campaign unfortunately also led to an unjustified demonization of all fluorinated technologies.

Perfluorooctanoic acid, also known as PFOA or C8, has been used in the manufacture of such prominent consumer goods as Teflon. It has been manufactured since the 1940s in industrial quantities. Despite offering outstanding performance characteristics, PFOA unfortunately also persists indefinitely in the environment and has been detected in the blood of more than 98% of the general US population. PFOA has been detected in, water, food, household dust and of course the human body. It has been used in the production of many items such as microwave popcorn bags, cookware, (PTFE / Teflon) cosmetics and carpet coatings.

Studies have concluded that there was probably an association between PFOA exposure and six health outcomes: kidney cancer, testicular cancer, ulcerative colitis, thyroid disease, hypercholesterolemia (high cholesterol), and pregnancy-induced hypertension.

As a result of these findings scientists around the world decided that a move towards C6 as a replacement technology may be appropriate.

Extensive testing has been carried out and C6 agents have been found to be safe: “*These compounds do not appear to possess the biopersistence and potent systemic and reproductive toxicity that are characteristic of C8-PFCs as a class. Instead, data from animal and epidemiological studies indicate that C6-PFCs are rapidly and completely excreted and do not appear to accumulate in biological fluids.”

*Rice, P.A. Curr Envir Health Rpt (2015) 2: 33. https://doi.org/10.1007/s40572-014-0039-3

Based on these findings it became apparent that an SiO2 + C6 variant could form the platform for a new form of PFOA / PFOS free coating.